Performance

Parts

We develop individual product solutions which meet specialised vehicle assembly requirements.

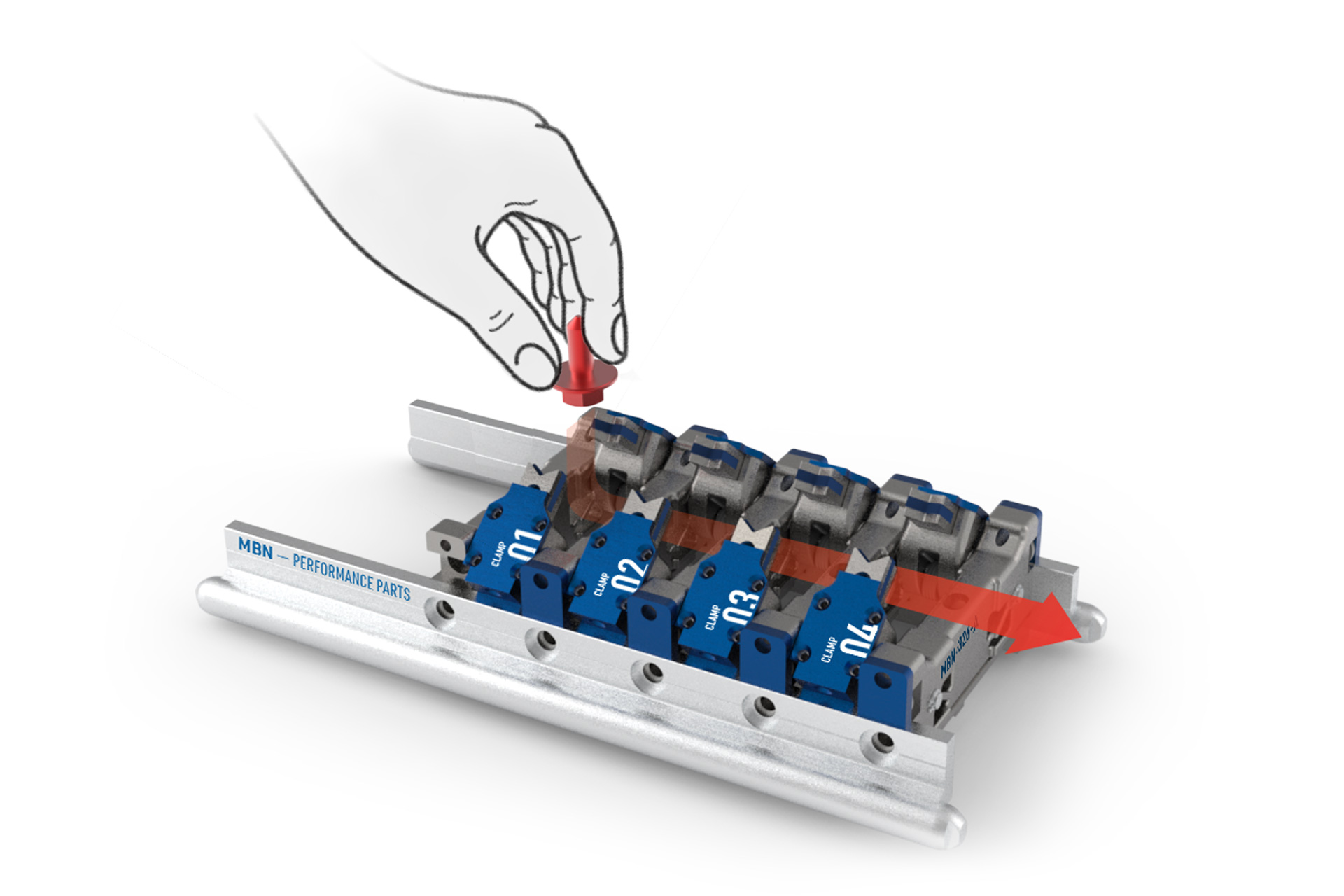

Direct screwing system

"Fastener-loader"

With our patented direct screwing system it is possible to fit a larger number of screws economically and efficiently in shorter cycle times without further aids.

The core of the solution is our patented magazine

Despite the reduction down to essentials…. 100% availability.

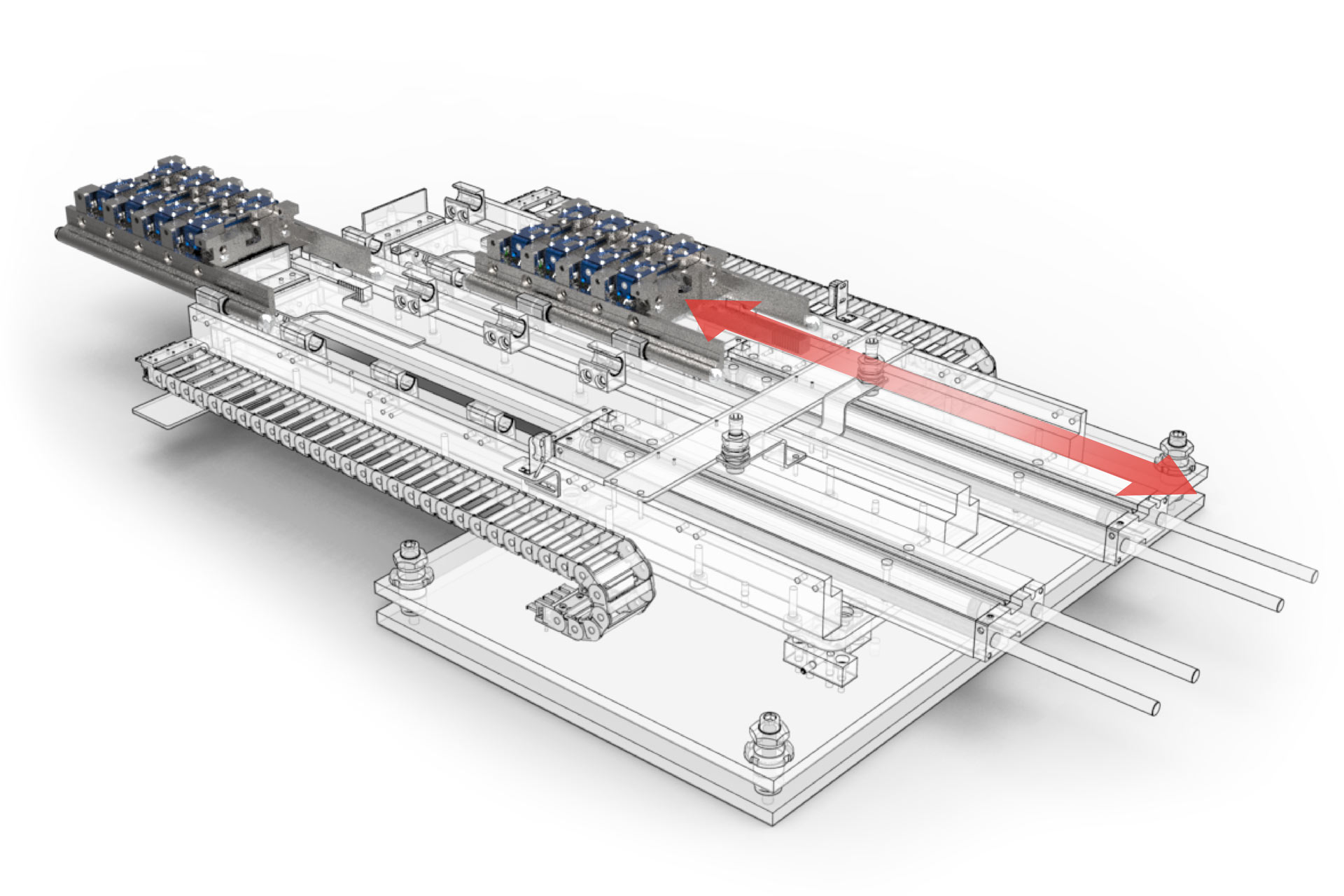

The compact design permits the FASTener LOADer to be integrated into/retrofitted to existing screwing equipment.

Screws of various sizes can be processed within one screwing cycle. Conventional screws from adaptor spindles can also be integrated by moving the magazine.

Reduction of elements to the essentials, tool-free magazine exchange, use of maintenance-free dirt-resistant bearings.

We bring the screws to where they are needed

With this system the screws become finished screw fittings out of the box via various routes.

Features

The construction was designed so that the FASTener LOADer offers the following features in relation to the competition.

Sustainability

Sustainability through reducing the necessary technical elements down to essentials.

Environmentally friendly

Environmentally friendly due to the use of lubricant-free materials.

Efficiency

Energy savings through reducing active drives and storage of potential energy in the magazine.

Low-maintenance

Reduction of elements down to essentials, tool-free magazine replacement, use of maintenance-free dirt-resistant bearings.

LOADING

THE MAGAZINE

01

Manual

Optimum utilisation of staff through the option of manual loading

02

Robot arm

In highly complex systems with short cycle times the magazines are loaded by means of robots.

03

Magazine changer

With applications with low cycle times, complete magazines are replaced to use the cycle time to the full.

Screw cast-off

variants

01

Internal

cast-off

This guarantees the further processing of screw cases of NOK screws without large cycle time losses.

02

External

cast-off

The screws are then completely cast off out of the system if NOK.

USE of the FASTENER LOADER

IN THE PORSCHE PROJECT

The magazine permits screws of various sizes to be processed.

Our solutions guarantee

a smooth process

Economical operation

Intermediate spindles and a secure screw clamp in the magazine are no longer needed without internal electric or pneumatic drives. Energy savings due to reductions in drives and controls and maximum adaptability to changing screwing processes. Reduction of NC screw spindles to a minimum.

Innovative technology

Function integration leads to lighter and less complicated technology. Energy which is accessed via external operating mechanisms is stored in the magazine.

Flexible operation

Screws of various sizes can be processed within one screwing cycle. Conventional screws from adaptor spindles can also be integrated by moving the magazine.

Low-maintenance

The tool-free exchange of magazines allows them to be cleaned and maintained during normal operation without losing time.